- INDUCTIVE AUTOMATION IGNITION SERIAL IP HOW TO

- INDUCTIVE AUTOMATION IGNITION SERIAL IP DRIVER

- INDUCTIVE AUTOMATION IGNITION SERIAL IP SOFTWARE

At the same time, travel costs are saved since Perspective can do all programming through a secure remote connection, and support costs decreased by $10,000. The DPW now has access to more data than ever. They can see clear across the room if any station is having an issue.” “Then back at the main facility they have a giant widescreen monitor that has an overview of all the stations.

“(The DPW) really liked that because all of their technicians in the field use iPads to pull up the Perspective project to log into the station,” Finkler said. This was also Perceptive’s first big project that used the Ignition Perspective Module. “The biggest thing to say about Ignition is everything connected right up and worked flawlessly,” he said. DPW also uses Ignition’s support for TLS encryption and certificates of trust to establish secure connections with each EPIC. To add security protection, the modems were firewalled to only permit specific IP addresses to connect. The DPW upgraded its radio network to 4G LTE cellular modems. “I would like to see more municipalities using Ignition or SCADA projects in general utilize MQTT for communication.” “There is such low latency the typical polling scheme that is the industry standard is incredibly slow by comparison,” Finkler said. The project has allowed the DPW system to go from multi-minute cycles to sub-second latency. This was the first time Finkler had used MQTT on such a wide scale, with each individual controller reporting to the SCADA controller, he said. That’s when Perceptive persuaded the DPW to consider Inductive Automation’s Ignition to manage its MQTT infrastructure and integrate seamlessly with its field devices. However, Waterford’s legacy SCADA system was unable to work with MQTT. In 2018, Waterford decided to adopt MQTT to handle their data transmission and was in the process of installing fiber connections in all of their stations. There is the concurrent requests setting which determines the number of simultaneous connections we open up to the PLC at any given time. My device's IP address is 10.20.4.55, and that's pretty much all we need to do. Since a lift station can run completely in under that time, operators could miss an entire cycle, Finkler said. The only other thing we need to do is in the hostname section, specify the IP address of the device. With the department’s serial polling scheme and the limited bandwidth of the radio network, data from each site could only be updated every three to four minutes. However, the replacements did not address some of the department’s ongoing issues. The DPW began upgrading field devices and SCADA system hardware. Waterford manages 715 miles of water and wastewater sewer pipe, including 63 sewer lift stations, 11 treatment plants, three storage tanks and 19 production wells. The department was using two GE iFix workstations using a custom poll/response protocol to monitor dozens of RTUs in a round-robin fashion. In 2015, Perceptive Controls began working with the DPW in Oakland County, Michigan, to replace their aging core SCADA infrastructure. This makes the DPW, to Perceptive’s knowledge, one of the first municipal departments to set up a cloud-based control system. However, in 2018, the Waterford Township Department of Public Works (aka the DPW), led the charge to put their SCADA information on an Amazon cloud server.

INDUCTIVE AUTOMATION IGNITION SERIAL IP SOFTWARE

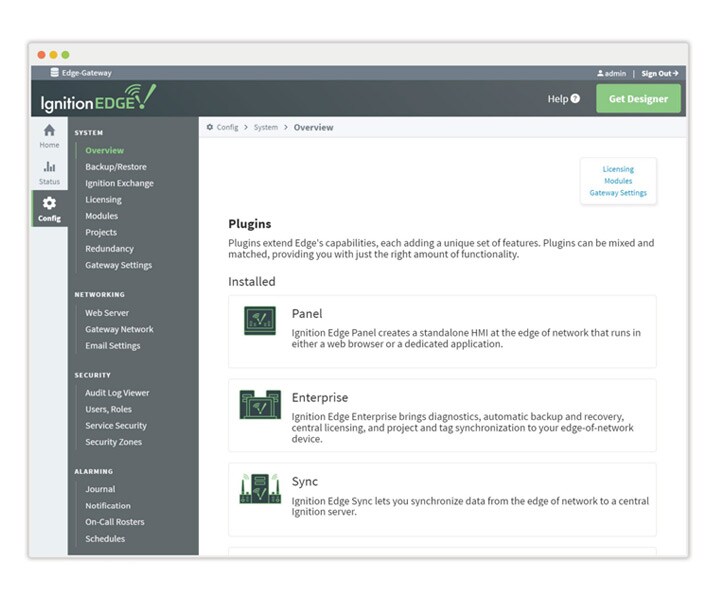

We can then scroll down to our quick client under OPC connections, expand the OPC folder and find our device and you'll notice all of our tags are in here.Some municipalities may be hesitant to put all of their SCADA information on a cloud server off-premises, said Kevin Finkler, software engineer at Perceptive Controls. And once it connects to the device, it'll automatically browse it for any tags. We then need to hit the create new device button at the bottom. And then for the host name property, we put the IP address of the PLC. We can then finish configuring the connection. Once we have that selected, we're going to scroll down and hit the next button.

INDUCTIVE AUTOMATION IGNITION SERIAL IP DRIVER

This driver can connect to older devices but it's optimized for devices with firmware version 21 and above. We're then going to click on the create new device link and make sure the Allen Bradley Logix driver is selected. The first thing were going to do is log into the configuration section of the Gateway webpage and scroll down to the device's page of our OPC UA server.

INDUCTIVE AUTOMATION IGNITION SERIAL IP HOW TO

Lets take a look at how to connect Ignition to an Allen-Bradley Logix family device that's using firmware version 21 or above.

0 kommentar(er)

0 kommentar(er)